HDG Hot Dipped Galvanized Ring Shank Wire Collated Coil Siding Nails

- Coil nails are ideal for all sheathing, framing and fencing applications.

- Fit all standard 15 degree pneumatic coil nails nailers. Jam free guarantee.

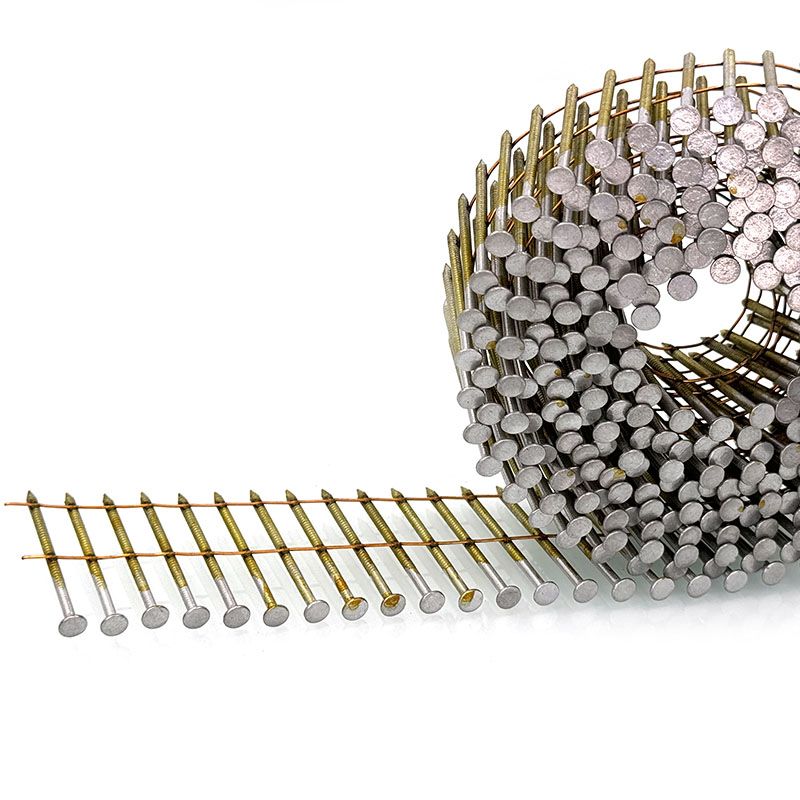

- Made from high strength steel. Copper wire collated.

- Vinyl coated, galvanized and hot-dip galvanized surface treatment are available.

- Smooth, ring or twisted shank available. Sharp points, easy to pin in.

- Reliable and sturdy, not easy to deform or break.

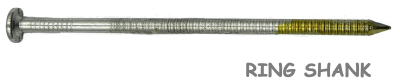

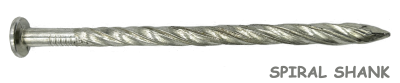

- SHANK TYPES:

Smooth shank coil nails are the most common ones. Used for framing and general construction applications. They can offer enough holding power for most use.

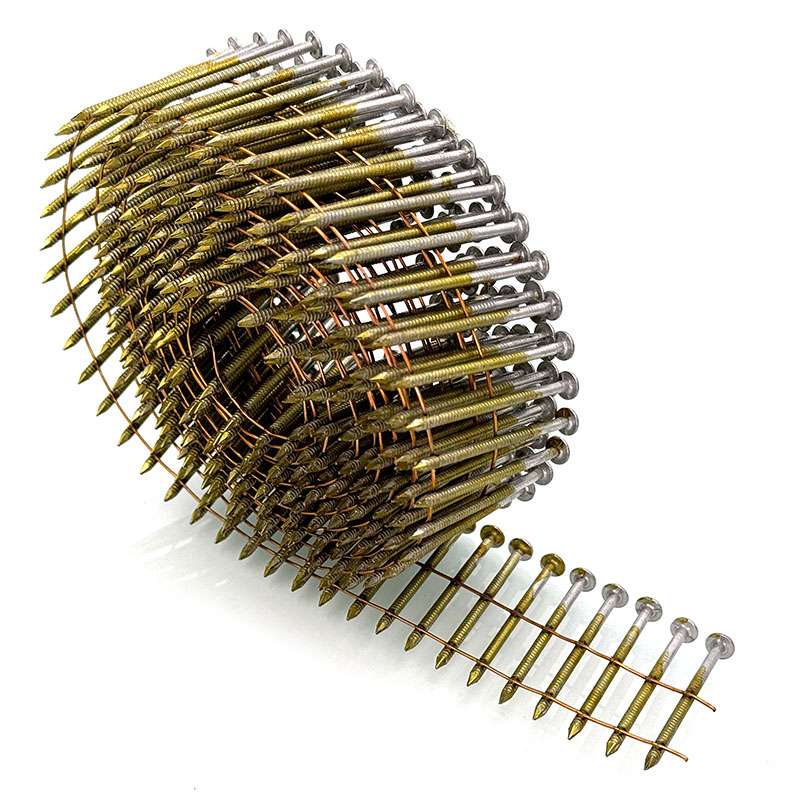

Ring shank coil nails prevent them from being removed as easily as smooth shank nails. Ring shank nails are often used in softer types of wood where splitting is not an issue.

Spiral shank pallet nails are generally used in hard wood to prevent splitting while the fastener is being driven. The fastener spins while being driven (like a screw) which creates a tight groove that makes the fastener less likely to back out.

- Packaging and Loading:

Coil nails are very commonly used in construction and carpentry.

Coil siding nails are made of high-quality steel that is coiled into a spiral or helical shape. This coiled design allows large quantities of nails to be held together in a compact form.

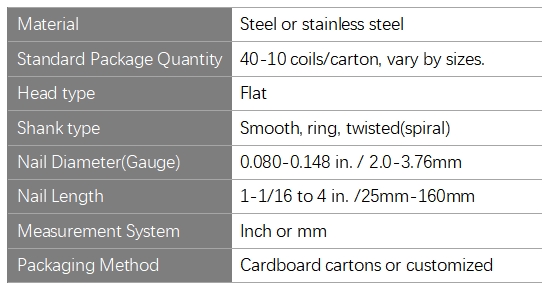

Varieties: We produce coil nailer nails in various lengths, diameters, and finishes to suit different applications. They are available in sizes ranging from 1-1/16 inches to 4 inches or more, with different shank types (smooth, ring, screw) for specific uses. Different surface treatment available.

Application: Coil nails are typically used with pneumatic nailers. The nail gun feeds nails from the coil without the need for frequent reloading, making it a best choice for professionals in the construction industry.

Benefits: The coil design of these nails allows for more nails to be loaded into the gun compared to bulk nails, faster reloading. The continuous feed system also helps improve productivity and efficiency on the job site.

Durability: Coil nails are manufactured to high standards using durable materials, making them suitable for heavy-duty applications. They are often coated with finishes such as galvanized or stainless steel to enhance corrosion resistance and longevity.

The cost of coil nails can be vary depending on the size, material, and quantity purchased. We offer packaing of cardboard cartons.